General information

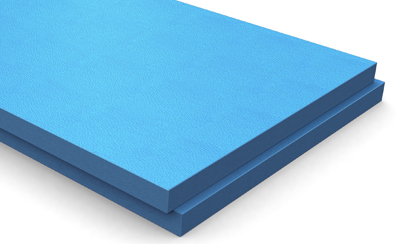

RAVATHERM XPS 500 SL thermal insulation with its closed cell structure is a perfect solution for the thermal insulation of heavy-duty inverted roofs, floor structures and load-bearing base slabs. High strength with little compressive deformation and excellent thermal insulation properties even in damp environment also in the long run.

Features

Other information

The blue-colour RAVATHERM™ XPS extruded polystyrene foam thermal insulation can be used in a wide range of applications, owing to the following beneficial properties as a result of the closed-cell material structure:

- permanently high thermal insulation level

- negligible moisture uptake

- high strength and rigidity

- dimensional stability

- resistance to rot and deterioration

- simple and quick installation with only a small amount of waste.

RAVATHERM XPS 500 SL is excellent thermal insulation for

Flat roofs

- green roofs

- parking roofs

Floors

- industrial floors

- foundation, base slabs

- cold storage floors

- swimming pool base slabs

BENEFITS

RAVATHERM XPS 500 SL thermal insulation is manufactured by extrusion production procedure, the result of which is a homogeneous, closed-cell material structure, a smooth surface crust (called extrusion crust) and numerous favourable material properties:

- permanently high thermal insulation performance,

- water and frost resistance,

- high compressive strength,

- high flexible rigidity,

- high vapor diffusion resistance,

which make the product suitable for fully meeting all the demands of the numerous application areas listed.

ADVANTAGES IN USE:

- „built-in” insulation-protection

- resistance to rot and deterioration

- high insulation performance over decades

- negligible moisture uptake

- low deformation under compression

- high E-modulus

- simple structural design and workability

- resistance to freeze-thaw cycles

RAVATHERM XPS 500 SL thermal insulation with its closed cell structure is a perfect solution for the thermal insulation of heavy-duty inverted roofs and floor structures.

RAVATHERM XPS 500 SL thermal insulation can be applied either above or below the reinforced base plate, even if laid down directly onto a compacted gravel bed. In this case the framework of the reinforced concrete floor structure can be assembled on top of the thermal insulation, or even the insulation of the building against soil moisture can be prepared here. Using this method, a layer of blind concrete can be saved, including all of its incremental costs.

RAVATHERM XPS 500 SL products can be laid down in multiple layers in floors and in floors on the soil.

Application fields

Other

SIZING

To determine the load-bearing capacity of floor structures also incorporating a thermal insulation layer for permanent and useful loads, the compressive strength values for permanent load must be used!

For the planning of reinforcement steel requirements of a floor slab working as a load-distribution structure over the thermal insulation layer, a structural engineer must be involved!

PLACEMENT OF RAVATHERM XPS 500 SL

Onto a concrete surface

The light-weight, easy-to-handle RAVATHERM XPS boards can be laid down simply and quickly without adhesives, with a closed gap.

Between the thermal insulation and the concrete screed layers, the placement of a PE film separating and sliding layer is recommended.

In slabs between levels, impact sound insulation must be resolved separately.

Onto a compacted gravel layer

RAVATHERM XPS thermal insulation boards are to be laid down in an offset bond, directly onto the compacted gravel layer of a thin blinding layer of concrete with sand equalization if necessary. The thermal insulation boards can be laid down simply and fast in any weather conditions. The boards can be cut to size by a handsaw or hot wire cutter. The cut surfaces can be accurately fitted.

Rebar installation

Thanks to the high strength, the spacers of the iron reinforcement will not penetrate into the thermal insulation boards, so the necessary clear concrete cover will be ensured everywhere. However, in the course of the fitting work, it is reasonable to walk on the thermal insulation or use load-distribution planks or flooring boards on the area already fitted.

Where the thermal insulation boards are installed above the insulation against soil moisture or ground water, they will also act as a mechanical protective layer during the time of construction, which is particularly favourable during rebar installation.

IMPORTANT

The permanent application temperature of RAVATHERM XPS products is max. 75°C.

At higher temperatures, the plates will melt and suffer permanent deformation.

RAVATHERM XPS products contain an – ecologically safe – flame-retardant additive, as a result of which they will be self-extinguishing under their ignition temperature, however, they will burn if exposed to an intensive ignition source.

RAVATHERM XPS products are resistant to commonly used construction materials not containing solvents or softeners (bituminous components without solvents, water-based wall protecting materials, lime, cement, masonry mortars and plasters, anhydrous gypsum etc.).

Certain organic materials, such as solvent-based wood preservatives, paint additives, solvents (acetone, ethyl acetate, kerosene, gasoline etc.) will cause softening, shrinking and damage to the material.

For gluing, solvent-free adhesives must be used. Follow the supplier’s guidance.

XPS products must not be exposed to permanent intensive direct sunlight.