General information

High-performance, multi-purpose polystyrene foam for the thermal insulation and frost protection of inverted flat roofs, cellar perimeter walls and floors with normal load.

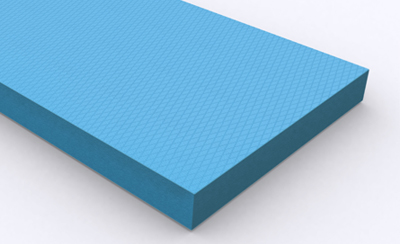

The RAVATHERM XPS 300 SL thermal insulation is manufactured by extrusion production procedure, which results in homogeneous, closed-cell material structure, smooth surface crust (called extrusion crust) and many favourable material characteristics.

Features

Other information

The blue-colour RAVATHERM XPS extruded polystyrene foam thermal insulation can be used in a wide range of applications as a result of the following beneficial properties thanks to the homogeneous, closed-cell material structure:

- permanently high thermal insulation level

- negligible moisture uptake

- high strength and rigidity

- dimensional stability

- resistance to rot and deterioration

- simple and quick installation with only a small amount of waste.

RAVATHERM XPS 300 SL is excellent for thermal insulation and for the protection of insulation in the following structures.

Flat roofs

- inverted roofs with gravel

- green roofs

- terrace roofs

- parking roofs

- duo roofs

- for refurbishment – plus roof

Structures in contact with the soil

- outer side of perimeter cellar walls

- perimeter walls in subsoil water

- underlying bodies, base slabs

- swimming pools

Floors

- standard building floors

- industrial building floors

- cold storage floors

- swimming pool base slab

BENEFITS

The RAVATHERM XPS 300 SL thermal insulation is manufactured by extrusion production procedure, the result of which is a homogeneous, closed-cell material structure, a smooth-surface crust (called extrusion crust) and numerous favourable material properties:

- permanently high thermal insulation performance

- water and frost resistance,

- high compressive strength,

- high flexible rigidity,

- high vapor diffusion resistance,

which make the product suitable for fully meeting all the demands of the numerous application areas listed.

Application fields

Technical

APPLICATION

INVERTED ROOF

Between the RAVATHERM XPS 300 SL thermal insulation boards, which are placed in a staggered manner without adhesives, and the ballast, which is generally a layer of gravel, a breathable, non-hygroscopic separation layer should be laid down with a 200-mm overlap, which together with the ballast layer provides the proper stability of the plates against wind load and floating.

In the case of inverted roofs, from a vapor diffusion aspect, an open design of the layer order above the thermal insulation must be used.

For utilized roofs with a closed order of layers from vapour diffusion aspect, it is strongly recommended installing a diffusion layer (at least 2 to 5 cm of gravel, crushed stone etc.) between the thermal insulation and the soil layers, tiles, load distributing reinforced concrete slab.

STRUCTURES IN CONTACT WITH THE SOIL

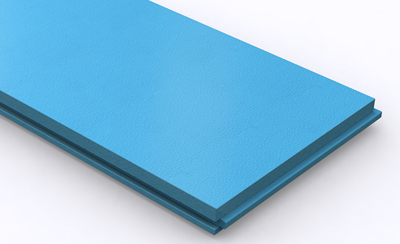

The RAVATHERM XPS 300 SL boards with staggered edge finishing which can be fitted without a thermal bridge must be fixed with a closed gap, applying adhesives pointwise in an offset bond (at six points per plate), or when PUR adhesive foam is used, it must be applied in strips.

The thermal insulation can be cut easily and accurately using hand tools.

The maximum installation depth of the thermal insulation is determined by the load: the horizontal pressure must not exceed the compressive strength of the plates, considering the value that pertains to permanent load.

FLOORS

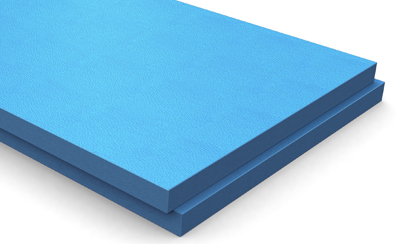

In the case of a compressed gravel bed or thin blind concrete, the RAVATHERM XPS 300 SL thermal insulation must be laid down directly in an offset bond, with sand levelling if necessary. If the thermal insulation is installed above the insulation protecting against soil moisture and ground water, it also serves as a mechanical protective layer.

In the case of normal floors and floor heating, the heavy-duty heat insulating layer provides a firm base for the base concrete (screed) and floor heating, where the heating pipes can be fastened directly to the thermal insulation. It is recommended to place a PE film separating and sliding layer between the thermal insulation and the base concrete (screed) layer. In the case of inter-floor slabs footstep sound isolation must be separately provided for.

IMPORTANT

The permanent application temperature of RAVATHERM XPS products is max. 75°C.

At higher temperatures, the plates will melt and suffer permanent deformation.

RAVATHERM XPS products contain an – ecologically safe – flame-retardant additive, as a result of which they will be self-extinguishing under their ignition temperature, however, they will burn if exposed to an intensive ignition source.

RAVATHERM XPS products are resistant to commonly used construction materials not containing solvents or softeners (bituminous components without solvents, water-based wall protecting materials, lime, cement, masonry mortars and plasters, anhydrous gypsum etc.).

Certain organic materials, such as solvent-based wood preservatives, paint additives, solvents (acetone, ethyl acetate, kerosene, gasoline etc.) will cause softening, shrinking and damage to the material.

For gluing, solvent-free adhesives must be used. Follow the supplier’s guidance.

XPS products must not be exposed to permanent intensive direct sunlight.