General inforation

Sport surfaces must be protected against frost to maintain the quality of the playing surface and to prevent the risk of unevenness and reduced bearing capacity during the thaw.

The most effective way to do this is to use thermal insulation beneath the surface, rather than excavate and replace large quantities of substrate. Insulated tracks enable the season to be significantly extended.

The spring sun will quickly thaw and dry out the surface layer so the season can start early. In the autumn a carefully built and well drained, insulated sports surface will be able to offer good conditions long after the frost has come. The long season is beneficial for users and maximizes the return on investment.

SKATING GROUNDS

The skating grounds must be insulated otherwise the frost can damage their foundation. Furthermore, insertion of insulation materials can result in energy saving, as well. The designing and construction of skating grounds is a complex task that can not be described in its entirety. The skating ground of the simplest structure consists of cooling tubes embedded in a gravel bed, complete with the pertaining cooling installation. For the purpose of building a skating ground of outstanding technical quality, the following aspects should be considered:

- anti-frost insulation of the soil, in order to avoid soil displacements caused by violent attacks of frost,

- integration of insulation, as to achieve energy consumption reduction, temperature control and fast creation/thawing of the ice,

- construction of a system of sports grounds, as to ensure utilization of the area in frost-free periods, as well.

Other information

In case of every structure, building or facility built upon soil completion of earth-works and construction of the substructure of proper quality is an indispensable task.

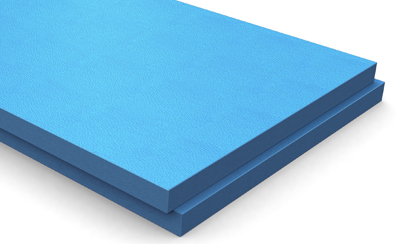

The design of the sports and football grounds is similar to that of roads of Category III. Spreading one layer of RAVATHERM XPS 300 SL or RAVATHERM XPS 500 SL over the entire surface is recommended, extending by 0.5 to 1.0 meter beyond the edges. The plates of straight edge should be laid maintaining 5 mm gap between them, as to ensure dewatering of the soil. Surface diversion should be ensured by laying thinner layer insulation over a 2 to 3 meter wide strip, where transition to the uninsulated surfaces is provided. The 250 to 300 mm thick stone bedding should consist of gravel or crushed stone of good quality.