General information

The pitched roof is the characteristic roofing solution of residential buildings, which allows for the full utilization of the space bounded by the roofing. In order to provide lasting comfort for the interior space, decrease heat loss, and avoid condensation, the professionally designed layer structure containing an efficient thermal insulation is key.

The efficiency of the thermal insulation prevails only if the thermal bridges are eliminated. The pitched roof’s thermal insulation above the rafters draws the whole roof into the insulated building envelope.

Other information

The application of high strength RAVATHERM™ XPS 300 ST thermal insulation installed onto the upper plane of the roofing in a way to make a continuous surface has a number of benefits:

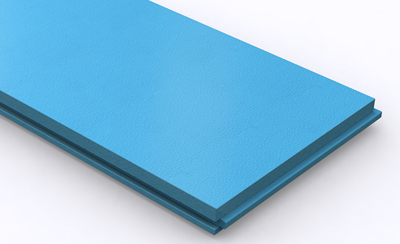

- the plates with tongue and groove edge finishing around their perimeters create a heat insulating layer with accurate fitting that is free of thermal bridges

- the moisture insensitive thermal insulation does not require protection against rain or snow during the implementation

- the plates are not damaged by the permanent loads (weight of cover, loading by snow and wind) imparted from the counter battens

- the whole supporting structure is thermally insulated, protected from tension caused by temperature fluctuations

- the high rigidity XPS boards work in conjuction with each other assisting with the stability of the roofing against horizontal loads

- installation is not dependent on the weather, it is a simple structural solution.

Technical

INSTALLATION

RAVATHERM XPS 300 ST plates that are mounted parallel to the eaves, starting from a plank with its height matching the thickness of the thermal insulation, should be laid down in an offset binding with a tight fastening. The placing of the thermal insulation must be started at the eaves. The plates must be placed in a brick bond, shifting the joinings in the subsequent lines, tightly fitting the interlocking bonds, thereby eliminating the formation of thermal bridges. In the case of ridges, roof superstructures, the gaps between the joints must be filled with PUR foam.

The counter battens must be drilled beforehand, preventing their cracking or splitting by using fastening elements. The fastening elements of the thermal insulation and the counter battens must be determined by the designer.

The fastening of the RAVATHERM™ XPS 300 ST plates is done using high strength galvanized nails or screws through the predrilled, at least 50 mm thick counter battens, based on the fastening plan prepared by the structural engineer.

Since proper load bearing capacity, adequate weather tightness and improved prevention of thermal bridge development are critical requirements beyond thermal insulation, correct installation of the XPS heat insulating plates can ensure achievement of the requirement in this regard.