General information

When the thermal insulation forms a spatial separation, mainly an external walling, between two “massive” structural elements, together with them, it is called core insulation (in the classical sense, for example, the external walls of precast concrete buildings).

Though these walls are layered structures, they still belong to the single-shell category, because there is no ventilated air layer between the layers.

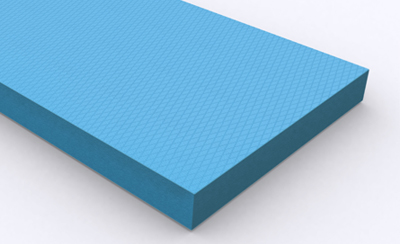

The factory (pre)fabricated sandwich panels where the XPS core forms an on-site assembled spatial partition together with the external and internal metal (possibly plastic or wooden) armour are also core insulations.

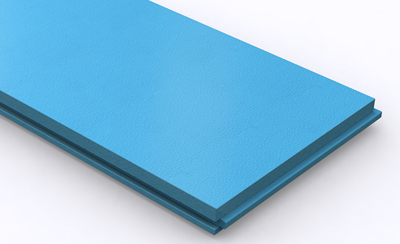

The RAVATHERM XPS 300 WB or RAVATHERM XPS 300 STG products can also be used in core thermally insulated structures. The advantage of the latter is the large board size and the tongue-and-groove jointing which makes it possible to use it as permanent insulated formwork or application along with the concreting technology from two sides at the same time.

The thermal insulation core installed in the expansion joint between two buildings may also be considered as a special core insulation.

Other information

Core insulated walls can also be manufactured by factory prefabrication (panel walls, sandwich panels) or on site. They are typically made with an internal structural layer, enclosed thermal insulation and external crust(-forming) layer.

Thanks to the advantageous characteristics of RAVATHERM XPS, in can be perfectly used with both construction methods, since, due to its closed-cell material structure, it practically does not take up construction moisture; due to its high strength, it endures both factory (pre)fabrication and on-site construction loads (feeding of bulk materials, compacting, vibration) without damage.

In prefabrication, the external cover of these walls is reinforced exposed concrete, while on site, it is more likely to be walled structure.

Technical

In the case of core-insulated single-shell reinforced concrete wall panels, the heat tolerance of XPS has to be considered. During a heat curing process, temperature may not exceed +75°C!

The thermal bridge effect of the connecting steel elements ensuring that the two external layers work together have to be taken into account by “oversizing” the core insulation or avoided by using connecting elements without thermal bridges.