General information

Efficient thermal insulation is an important aspect in case of the floor structure of cold-storage warehouses in order to ensure maintenance of the desired permanent inside temperature, beyond saving precious energy.

The reversed flow of moisture versus the generally moderated spaces should be taken into consideration. Such flow should be construed as the flow of relatively high moisture content present in the outside medium of higher temperature towards the colder (dry) interior space of low moisture content, via diffusion through the space limiting structures.

Other information

Distinction should be made between the stages of cooling (+ 10oC - 0oC - deep freezing) and both the thickness of the thermal insulation and the vapor control of the space limiting structures must be dimensioned accordingly.

Since the thickness of the thermal insulation layer exceeds, in several cases, 200 mm, the use of a high-strength heat insulating material is particularly justified, while taking care of the continuity of the entire surface involved, i.e. the floor, sidewalls and ceiling.

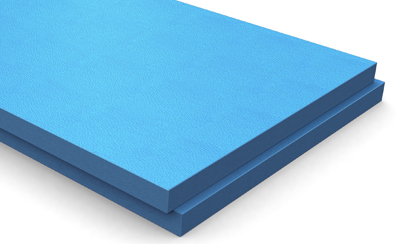

The manufacturing procedure of extruded polystyrene (XPS) plates produces a homogeneous, closed-cell material structure having smooth surface skin (the so-called extrusion crust) which features various favorable characteristics, like:

- permanently high insulation co-efficient,

- water and frost resistance,

- high strength,

- high elastic rigidity,

- high resistance to damp diffusion

Such favourable properties make the XPS thermal insulation material suitable, beyond other applications, for the perfect implementation of cold-storage warehouses/cooled spaces.

Technical

The use of high-strength XPS plates of high thermal insulation coefficient enables the development of cost-saving and load distributing reinforced concrete structures.

It is recommended to handle the increased thickness by installing two or more layers or by applying staggered edge finishing or tongue and groove edge finishing of the plates.

The thickness of the thermal insulation shall vary in function of internal cooling temperature and the maximum heat flow permitted for the cost-saving operation of the cooling equipment. The value of the maximum heat flow can be used to determine the heat transfer co-efficient of the limiting structures and, thus, the necessary thickness of the thermal insulation layer.

Heating of the soil beneath the heat insulated floor structure of deep cooling facilities can become necessary, in order to avoid freezing of the frost-sensitive soil layers.