General information

Simultaneously with the growing demand for excellent energetic performance, increasing emphasis has been laid on providing thermal insulation also to under-ground parts of buildings, i.e. the foundation bodies, incl. strip foundations or slab foundations built beneath the entire building.

Besides the reduction of downward heat flows, satisfaction of the thermal percep-tion expectations and protection of the structure’s integrity are tasks to be accom-plished.

The temperature of the floor should not differ from the temperature of the heated air by more than +/- 3o C, and no condensation of damp is permitted either at the floor surface or inside the floor structure!

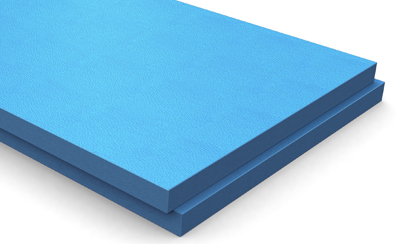

The RAVATHERM XPS thermal insulation products perform exquisitely also at such places exposed to humidity.

Other information

For the purpose of designing and selection of thermal insulation materials being in direct and permanent contact with the slab foundation built beneath the entire building, lasting and efficient operation can be ensured by choosing the RAVATHERM XPS 500 SL product, at the least or, for better static performance, the RAVATHERM XPS 700 SL.

The use of XPS products for the thermal insulation of reinforced concrete slab foundations results in the following advantages:

- permanently good thermal protection, despite the permanent presence of moisture

- subsequent building on and compaction shall not cause damage of materials

- no groundwater pollution is experienced.

Integration of the XPS thermal insulation in the slab foundation built beneath the entire building will ensure anti-freeze protection of outside segments above the frost-line, in addition to ensuring thermal insulation of floors inside the building.

Technical

The XPS thermal insulation in the slab foundation built beneath the entire building should be laid only on precisely prepared and carefully compacted and smoothed subgrade.

The thermal insulation should be built beneath the load bearing structure only after having completed proper static dimensioning.

Only the thermal insulation's ability to withstand permanent load can be taken into account for static dimensioning.

The RAVATHERM XPS thermal insulation products should be laid in an offset binding, directly on the compacted gravel bed or a thin blinding layer of concrete, complete with sand leveling, if necessary.

The need to prevent displacement of softening materials (e.g. PP felt or geotextile) can require insertion of separation course between the waterproofing course containing softening materials (e.g. soft PVC) and the XPS layer. The necessity of inserting a separation course must be declared by the manufacturer of the waterproofing material.

Staggered edge finishing or tongue and groove edge finishing of the XPS plates will guarantee their placement free of thermal bridges.

The XPS thermal insulation materials must be protected from effects of excessive temperatures (melting heat, welding) because they can be exposed to max. +80oC heat load, only for a short time.