This e-learning module will provide an overview of Ravago Building Solutions, applications for the company’s range of insulation products, and key information about the order and delivery process. We anticipate it will take you approximately 30 minutes to read the course material and complete the validation questionnaire.

Despite the current challenges facing the construction industry due to the coronavirus pandemic, the below information is still accurate. Ravago Building Solutions continues to manufacture construction products and deliver them to customers within target timescales.

Ravago Building Solutions is Europe’s largest extruded polystyrene (XPS) insulation manufacturer. Ravatherm XPS X is the new name for the UK’s best performing range of insulation boards for roofs and floors, all which have exceptional performance. Ravatherm XPS X has replaced the Dow Building Solution’s legacy brands of XENERGY™, STYROFOAM™ and FLOORMATE™.

| Dow Branding | Ravago Branding |

|---|---|

| XENERGY™ 300 SL | Ravatherm XPS X 300 SL |

| XENERGY™ LG | Ravatherm XPS X UB300 |

| XENERGY™ MK | Ravatherm XPS X MK |

| FLOORMATE™ 300-AP | Ravatherm XPS X 300 SB |

| FLOORMATE™ 500-AP | Ravatherm XPS X 500 SL |

| FLOORMATE™ 700-AP | Ravatherm XPS X 700 SL |

With a strong heritage and UK manufacturing stretching back 60 years, the extensive range of Ravatherm XPS X products offers architects and building specifiers unparalleled flexibility and the ability to meet the most creative of design specifications.

Ravatherm XPS X products are made and despatched from King’s Lynn in Norfolk, where Ravago Building Solutions began making the UK’s first-ever range of XPS insulation products 60 years ago.

Fundamentals of insulation

Insulation products are available in a wide array of materials, each offering different thermal and structural properties.

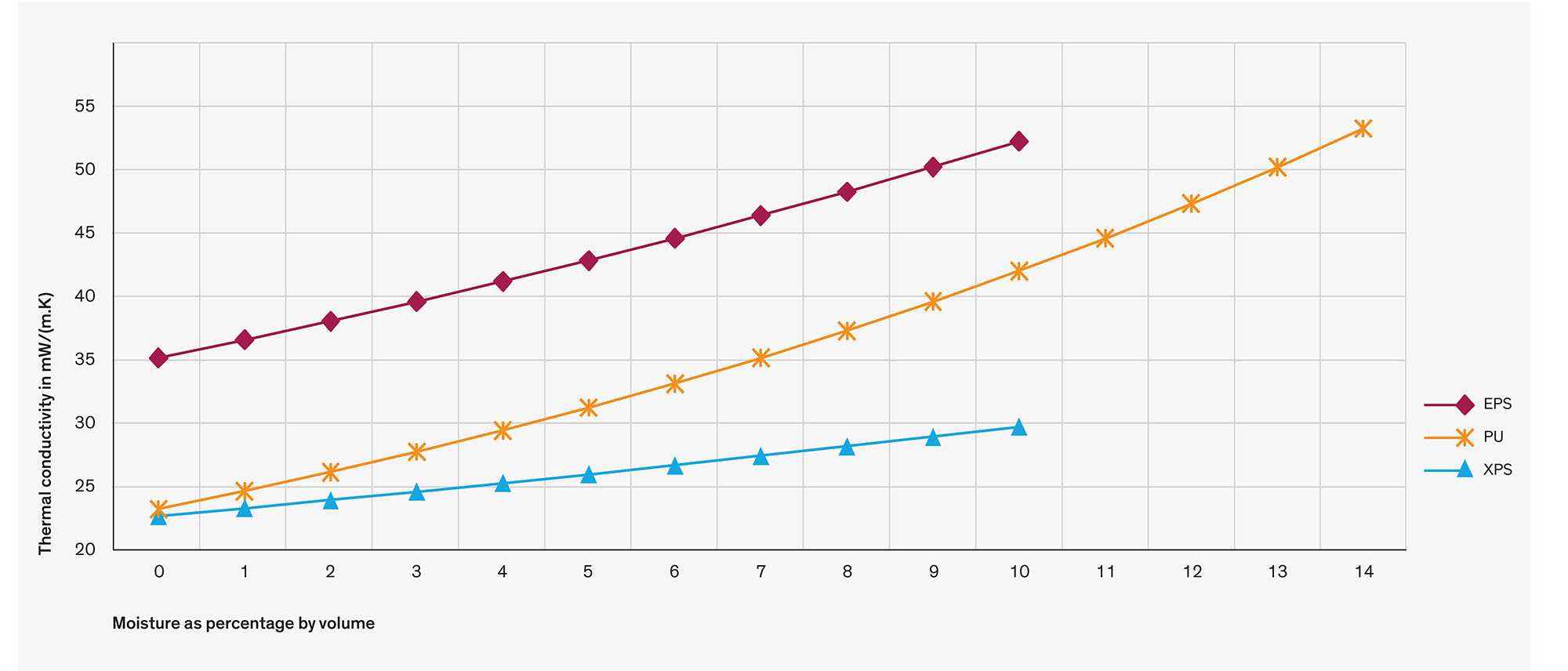

Lambda Values

The Lambda value of a building material is the expression of its thermal conductivity – the lower the value, the greater the thermal efficiency. Thermal conductivity is the rate that heat is transmitted through a material and is measured in watts per square metre of surface area for a temperature gradient of one Kelvin per metre thickness (W/mK).

| Material | Typical Lambda Value |

|---|---|

| Ravatherm XPS X | 0.031 W/mK |

| EPS insulation | 0.038 W/mK |

| Rock or glass fibre insulation | 0.040 W/mK |

| Softwood | 0.120 W/mK |

| Plasterboard | 0.170 W/mK |

| Blockwork | 1.170 W/mK |

Compressive Strength

The compressive strength of a material is its ability to withstand pressure squeezing the material together eg. heavy loads being placed on top of it. It is expressed in kilopascals (kPa), with a higher kPa meaning a greater compressive strength. Insulation boards with higher compressive strength are better suited for heavy-duty applications eg. car park decks or industrial environments with heavy equipment.

Benefits of XPS compared to EPS & PIR

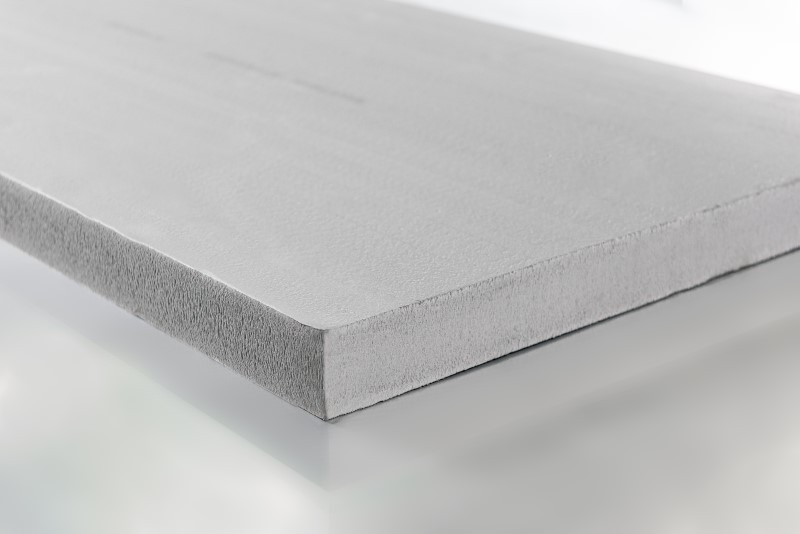

All Ravatherm XPS X products are comprised of extruded polystyrene (XPS), a rigid form of insulation. XPS boards made by extrusion, a continuous process which results in a smooth skin on the top and bottom of each board and a closed cell structure which provides many favourable properties.

EPS boards are expanded polystyrene, comprising small foam beads that have been fused together, forming an open cell structure with voids between many of the beads. The voids in an open cell insulation product will fill with air or water increasing their thermal conductivity, which has a negative impact by decreasing the thermal performance. These boards are also vulnerable to frost and have a lower compressive strength. It is essential that EPS and XPS boards are not confused.

PIR (Polyisocyanurate) boards are often supplied with an aluminium foil facing. PUR and PIR are Polyurethane and Polyisocyanurate respectively, a different kind of polymer insulation, which offer some advantages vs EPS such as lower water absorption. However, neither PUR nor PIR can achieve the higher compressive strengths required in inverted roof solutions and their water absorption is higher than XPS.

Ravatherm XPS X products and applications

Ravatherm XPS X was originally developed to deliver improved thermal performance for inverted flat roof applications, however, the increased thermal performance delivered by the technology is now also available in products for floor applications.

Exceptional thermal performance has been achieved through the addition of infra-red ‘blockers’ or particles. These are finely dispersed in the cell walls which scatter and reflect heat radiation, helping to keep a building warm in winter and cool in summer.

Ravatherm XPS X uses carbon dioxide as a blowing agent, which gives it an ozone-depleting potential (ODP) of zero and a Global Warming Potential (GWP) of less than five.

Product variants

The compressive strength of Ravatherm XPS X products is indicated in the product name and the boards will have one of two edge profiles;

- Butt – a flat edge where the boards simply touch each other.

- Shiplap – a grooved edge allowing boards to overlap, minimising gaps.

| Name | Main Application | Compressive Strength | Butt Edge | Shiplap Edge | Cement Fibre Top |

|---|---|---|---|---|---|

| Ravatherm XPS X 300 SB | Flooring | 300 kPa | ✔ | ✖ | ✖ |

| Ravatherm XPS X 300 SL | Inverted Flat Roofing | 300 kPa | ✖ | ✔ | ✖ |

| Ravatherm XPS X UB300 | Parapets & Upstands | 300 kPa | ✔ | ✖ | ✔ |

| Ravatherm XPS X 500 SL | Flooring & Car Decks | 500 kPa | ✖ | ✔ | ✖ |

| Ravatherm XPS X 700 SL | Heavy Duty Flooring | 700 kPa | ✖ | ✔ | ✖ |

The design compressive strength for Ravatherm XPS X that takes into account compressive creep can be found within the Technical Data Sheet (TDS) for each product.

Complementary Products

Fire Safety

Ravatherm XPS X contains a flame retardant additive to inhibit accidental ignition from a small fire source and has achieved Euroclass E for reaction to fire BS EN 13501 – 1. However, fire classification is based on small scale tests, which may not reflect the reaction of the product in its end use state under actual fire conditions. Ravatherm XPS X is combustible and if exposed to an intensive fire may burn rapidly. During shipment, storage, and installation Ravatherm XPS X products should not be exposed to flames or other ignition sources.

Once the insulation is placed in the inverted roof, if the finishing used is that covered by the European Commission Decision EC 2000/553/EC, the designation of the roof is Broof(t4) hence complying with Requirement B4 (External Fire spread) of Approved Document B of the Building Regulations. This is effectively using loose-laid gravel with a thickness of at least 50 mm or a mass ≥ 80 kg/m² (minimum aggregate size 16 mm, maximum 32 mm); Sand/cement screed to a thickness of at least 30 mm; Cast stone or mineral slabs of at least 40 mm thickness.

Construction applications

Ravatherm XPS X is designed for use in a wide range of roofing and flooring applications;

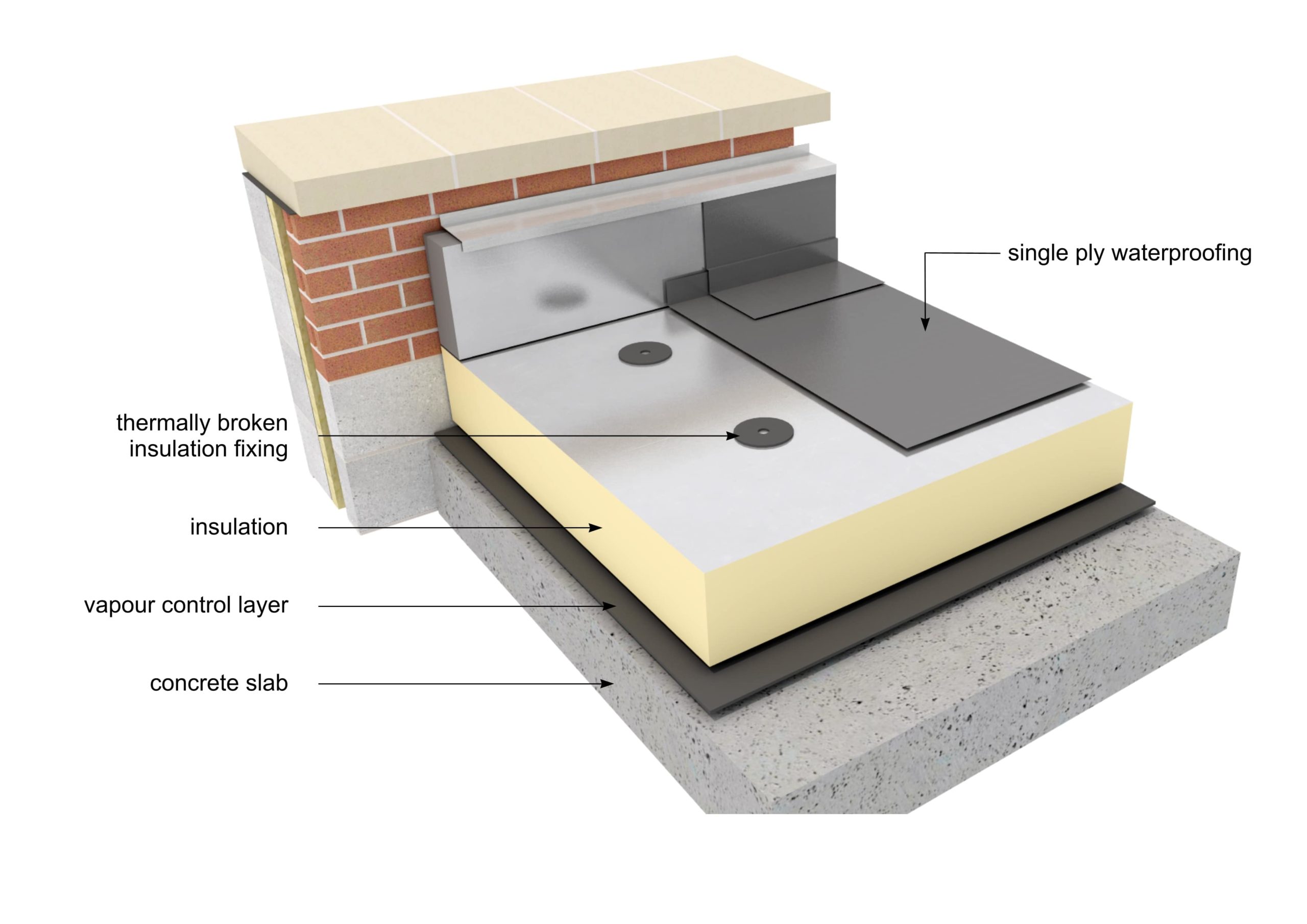

Inverted flat roofs

The thermal insulation of flat roofs is an important issue both for winter chill and summer heat, ensuring the efficient reduction of outbound heat flows from a structure when it is being heated and significantly reducing the need for air conditioning.

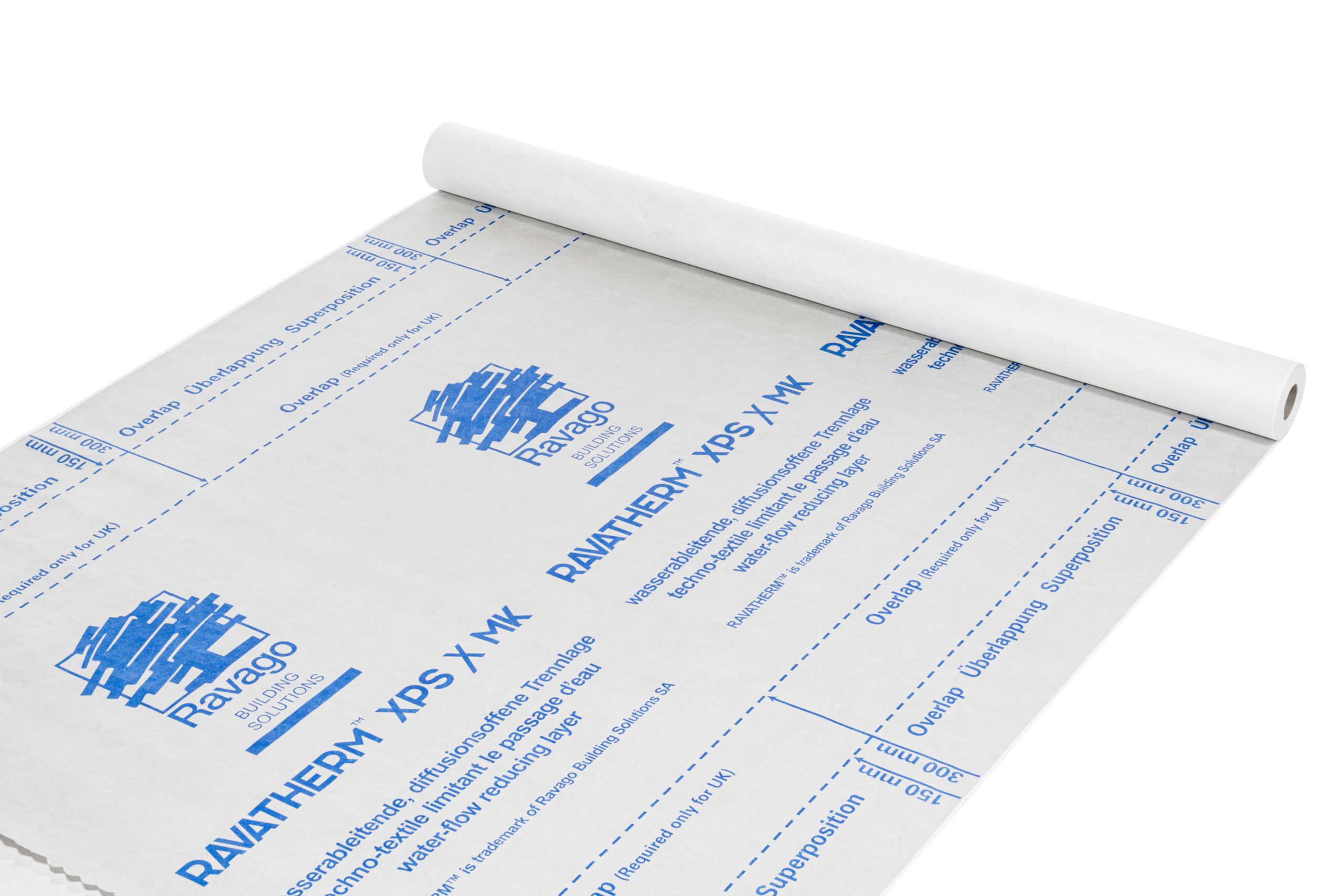

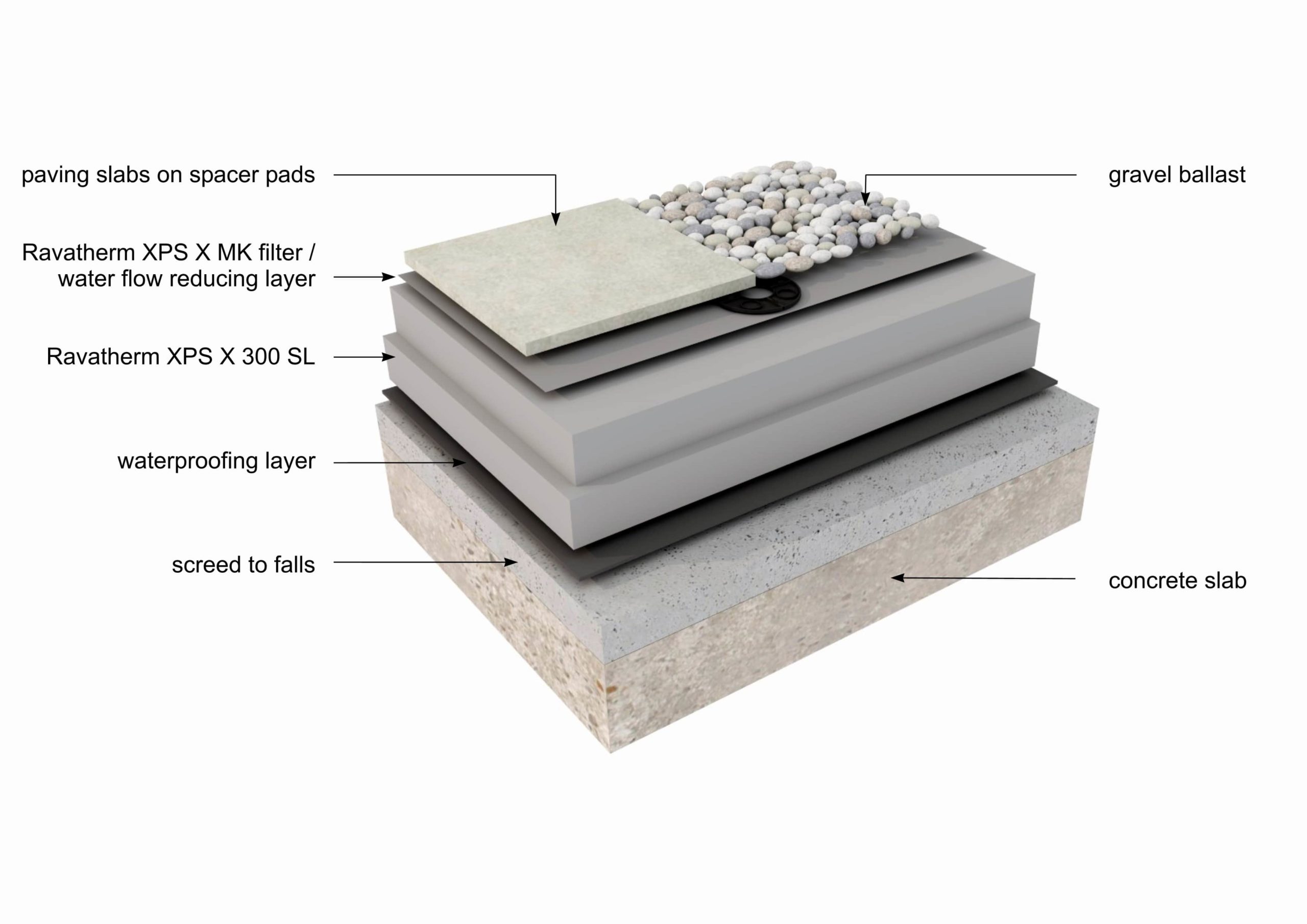

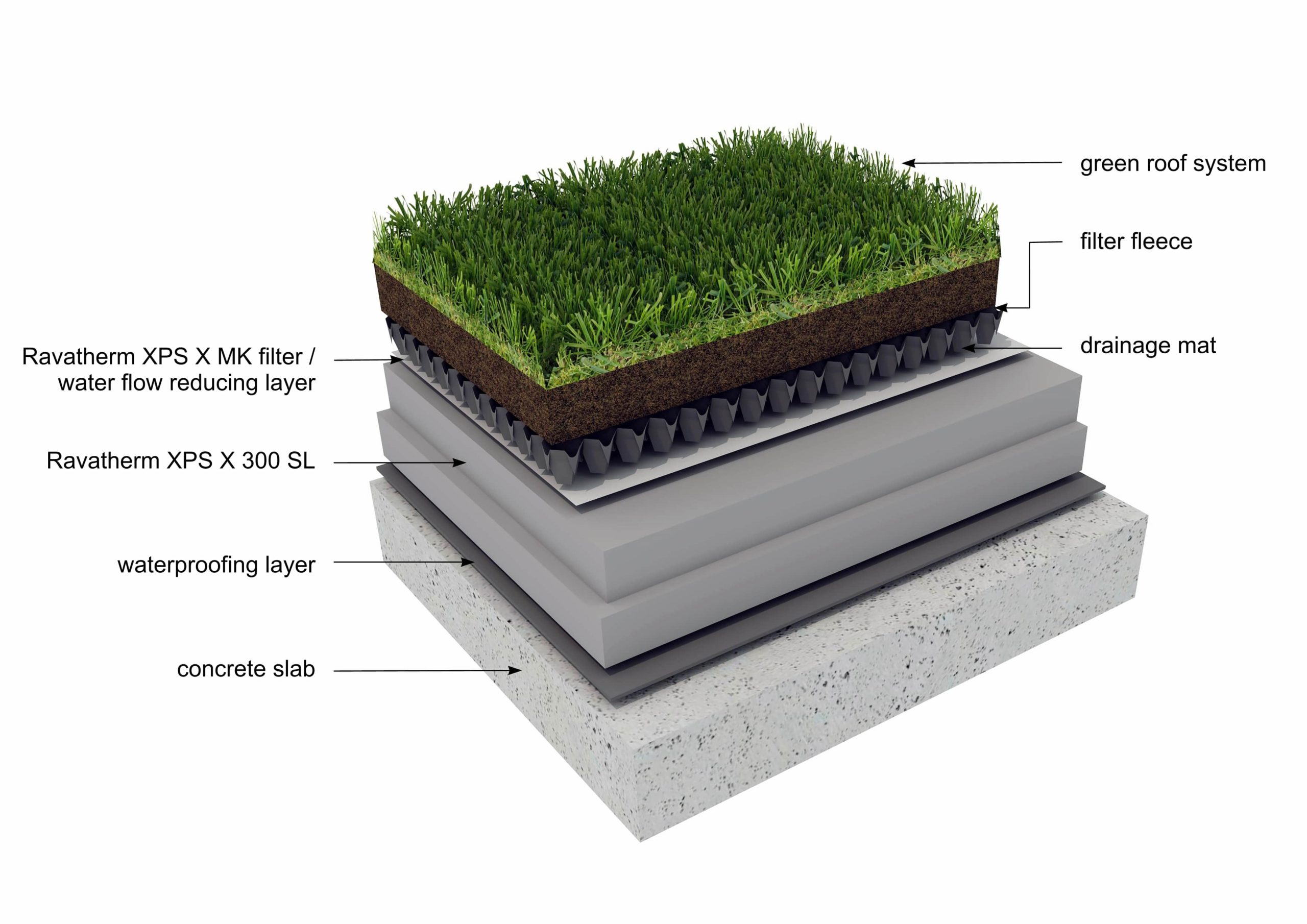

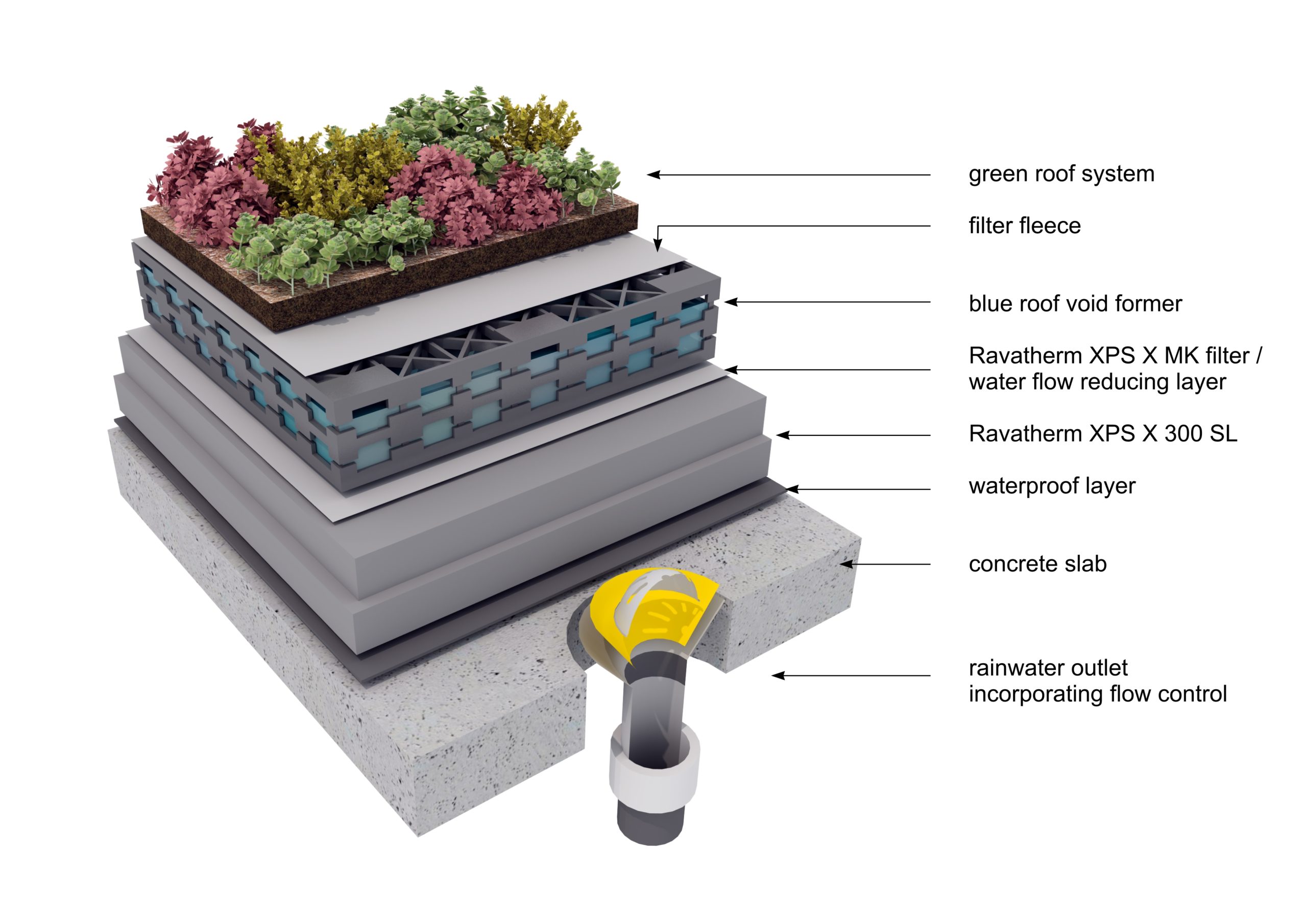

In an inverted flat roof build-up, unlike in a conventional warm roof, the waterproof roofing membrane is installed directly on top of the structural deck and is protected by the insulation layers without the need for an additional vapour barrier. A water-flow reducing layer (WFRL) is placed on top of the insulation which is then held in place by either paving slabs or gravel ballast. The WFRL should not be confused with the waterproofing layer and this essential component minimises heat loss due to the rainwater cooling effect.

In a conventional roof, the insulation is placed underneath the waterproof roofing membrane. Ravatherm XPS X should NOT be used in a conventional roofing system.

Inverted flat roofs comply with the building energy requirement that thermal protection should be unbroken and installed on the outside surface of the building structure. There are several different types of inverted flat roofs and all of them follow the principles outlined above;

Inverted flat roofs

The most conventional inverted flat roof application which uses paving slabs or gravel as ballast.

Green roofs

Vegetation is used as the ballast, reducing the load on the rainwater drainage system, delivering a better heat balance on the roof, creating an excellent microclimate and providing considerable carbon dioxide binding ability. The lower load provided by vegetation means this is an excellent solution in both a technical and ecological perspective.

Blue roofs

Water retention systems incorporated into a green or conventional roof store water for a short period, slowly releasing water to the sewer system in a controlled way, removing a potential cause of flash flooding following a severe storm. This is also known as SuDS (Sustainable urban drainage system) and is becoming more and more common in urban areas.

Roof terraces

Designed to be accessible to pedestrian foot traffic using decorative paving bedded in a screed or overlaid with paving slabs on spacers. The structure may also accommodate vegetation in planters or shading structures.

Car park decks

Constructed to accommodate the high loads generated by vehicles moving and being parked on a paved surface. Rooftop parking is a practical way of utilising the often large, flat surface roof area of commercial buildings, such as shopping malls, and residential buildings, where land area is at a premium.

Floors

Uninsulated floors bearing on or suspended over the ground, or over unheated areas, can be responsible for significant heat loss from a building. In addition to reducing the heat loss, good floor insulation significantly helps to increase overall levels of comfort by ensuring the internal temperature remains controlled despite fluctuating external temperatures.

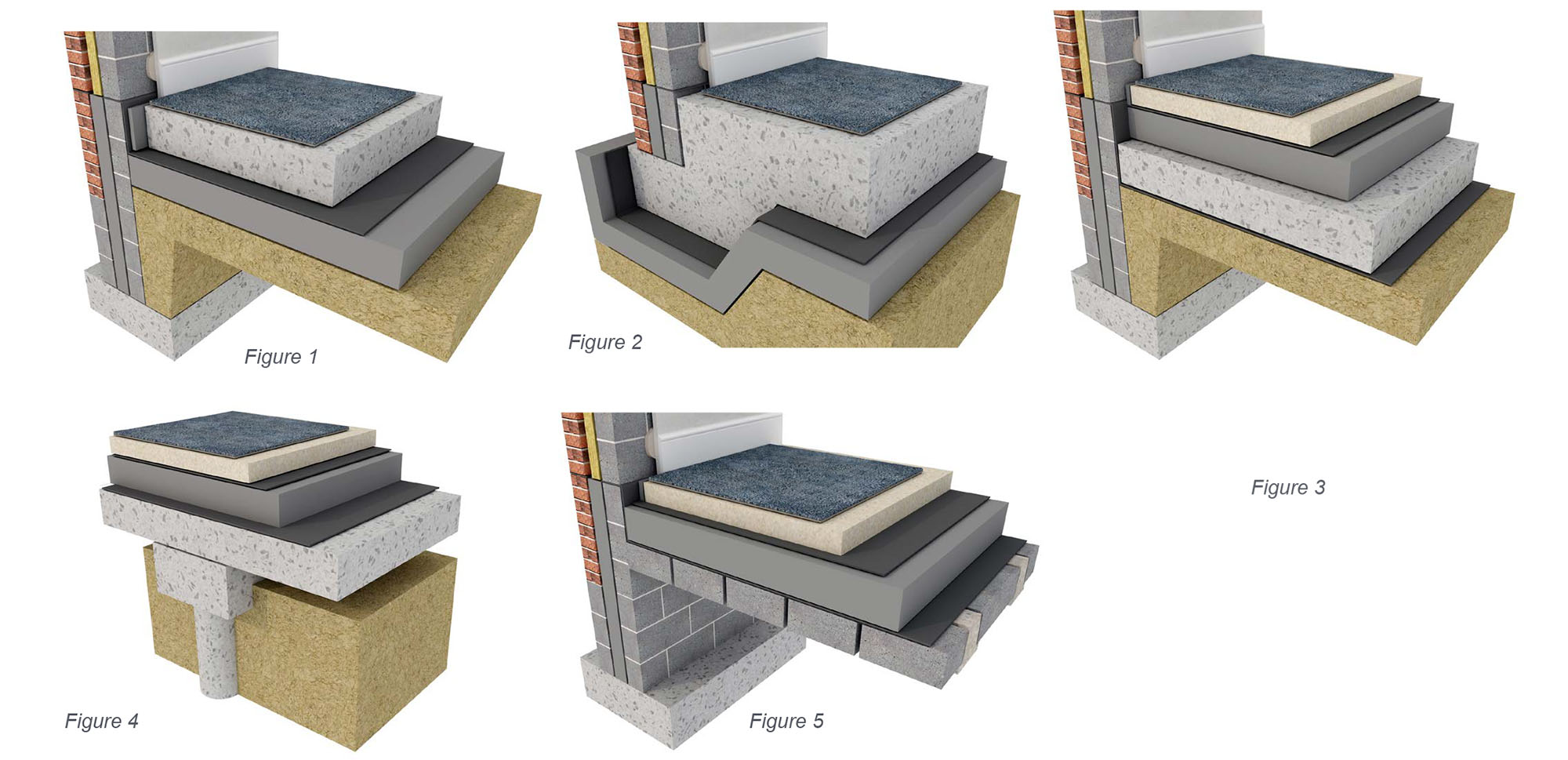

Above ground bearing slab

Figure 1 – Strip foundation together with a ground bearing concrete floor

Figure 2 – Raft foundation

Below ground bearing slab

Figure 3 – Strip foundation with a ground bearing concrete floor, and screed finish

Above a suspended slab

Figure 4 – Pile foundation with suspended concrete floor and screed finish

Figure 5 – Strip foundation with a beam and block suspended floor and screed finish

The compressive strength requirements will determine which variant of Ravatherm XPS X is most appropriate. Ranging from 300 kPa to 700 kPa, Ravatherm XPS X is suitable for everything from residential flooring to cold stores to aircraft hangars.

Example use cases

|  |  |

| 300 kPa Residential and Commercial | 500 kPa Car Parks | 700 kPa Aircraft Hangars |

Basements

In family homes with a basement, approximately 20% of the building’s total heat loss can be attributed to the basement walls, which can also contribute to surface condensation if lacking a proper insulation solution. All rooms in direct contact with the soil should have enhanced thermal insulation to minimise heat loss, prevent the development of cold bridges at footings and to avoid undesirable condensation.

Ravatherm XPS X can be used for thermal insulation of many elements of a basement, including;

- Basement retaining walls

- Basement floors

- Swimming pools

Why should you choose Ravatherm XPS X?

Certified performance

Ravatherm XPS X was the first XPS insulation product to receive a BRE Green Guide Rating A+ for roofing applications, and the product line is also rated A for flooring. The BRE Green Guide to Specification provides an assessment of the environmental impact of building materials and components across their lifespan using a rating system from A+ to E. This is an essential tool in the compilation of BREEAM (BRE Environmental Assessment Method) studies; this accredited programme is the world’s leading sustainability assessment method for master planning projects, infrastructure and buildings.

The British Board of Agrément (BBA) provides a certification scheme for building products, assuring end-users on the condition that correct installation procedures are followed. Purchasers of products with a BBA certificate can have confidence in their specification and that the performance models will be realised. Ravatherm XPS X 300 SB and Ravatherm XPS X 300 SL both benefit from BBA certification.

Benefits of high performance

All Ravatherm XPS X products offer exceptional thermal performance as demonstrated by their lambda value. This performance means that customers can meet their target U-values with thinner insulation boards, providing for additional design flexibility. Cost savings can also be realised with Ravatherm XPS X as alternative solutions will require increased quantities of insulation due to achieve the same thermal performance.

Ravatherm XPS X offers superior compressive strength compared to EPS or PUR/PIR, meaning it can be used in heavy duty applications. The insulation boards are suitable for everything from residential flooring to cold stores to aircraft hangars.

UK manufacturing

Ravatherm XPS X is produced at Ravago Building Solution’s manufacturing facility at King’s Lynn in Norfolk. UK manufacturing means that all Ravatherm XPS X products have a short lead time of just 3-4 days for delivery to site.

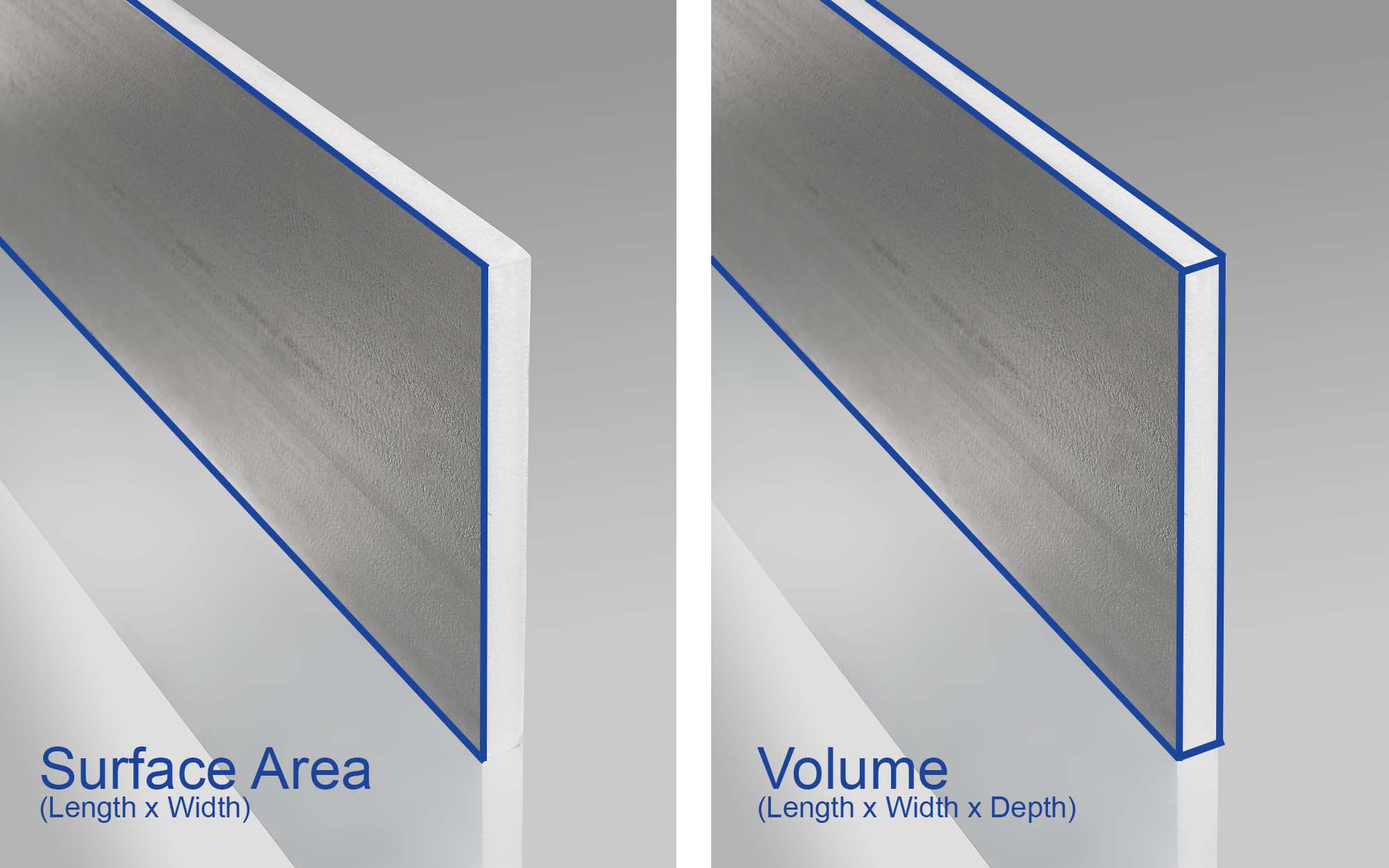

Different methods of expressing job sizes

The size of an individual job can be expressed in terms of surface area coverage (m²) or insulation material volume (m³). Different companies favour each measure, however, it is relatively easy to convert between the two. N.B You MUST have the insulation layer thickness to do this calculation as you are moving from 2D to 3D or vice versa.

Services provided by Ravago Building Solutions

Current and prospective customers can benefit from a wide range of services provided by Ravago Building Solutions.

Technical Services

A dedicated team of specialists can provide advice and support during the design stages of a project, providing detailed U-value calculations and other technical information. U-value calculation requests can be made via the Ravago Building Solutions website: https://ravagobuildingsolutions.com/uk/en/u-value-calculation-request/

Customer Service Team

Ravago Building Solution’s has a customer service team based at its manufacturing plant in King’s Lynn that can answer common questions about stock availability, logistics, pricing, PODs and invoices.

| Franki Jarman | 03300 606017 | franki.jarman@ravago.com |

| Odeta Makneviciute | 03300 606007 | odeta.makneviciute@ravago.com |

| Amanda Steward | 03300 606015 | amanda.steward@ravago.com |

| Debbie Brooks | 03300 606016 | debbie.brooks@ravago.com |

Ravatherm App

A free digital tool for architects, specifiers and members of the construction industry, providing quick and easy access to product information about Ravatherm XPS X, Ravago Building Solution’s market-leading range of thermal insulation. App users can also find essential technical data, gain an understanding of how to place and receive product orders, and perform initial U-value calculations for inverted flat roof and flooring applications.

Ravatherm App can be accessed at https://ravathermapp.com/ and can be installed on most modern mobile devices for offline use.

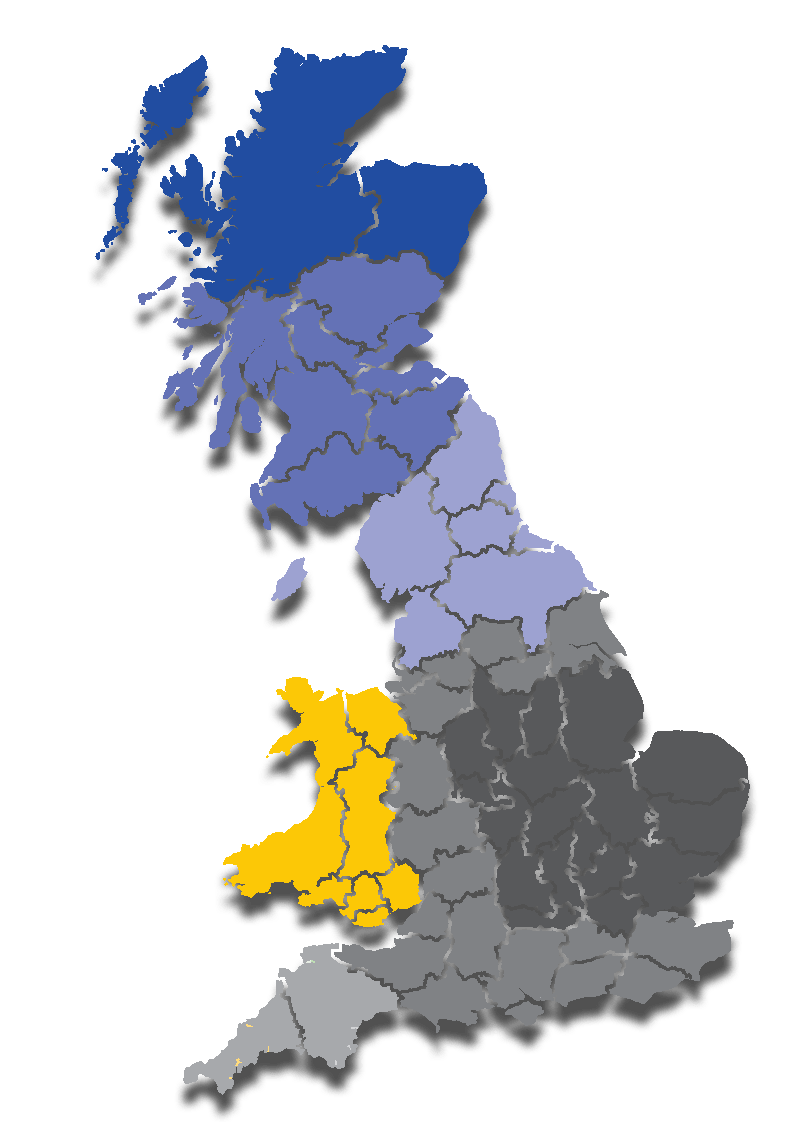

Deliveries

Deliveries are available to mainland England, Scotland and Wales, with a lead time of 3-4 working days from the time an order is received.

Following feedback from customers, Ravago Building Solutions recently invested in the packaging line at King’s Lynn to make it easier for product to be offloaded at delivery and to be transported across the site.

Ravatherm XPS X is available in packs and bulk units specific to each product and thickness.

The approximate weight of a bulk unit is 500kg, they are jumbo-sized 2.5×2.5× 2.5-2.95m (height differs depending on product) and supplied on foam bearers. Please Note: Unless otherwise requested when loading building products onto curtain sided vehicles, the bulk unit outer wrapping will be pre-slit allowing for access and offload with standard forklift.

Minimum quantity for deliveries is 1 bulk unit (with a carriage charge). Standard deliveries are on curtain-sided articulated vehicles (provided by Jack Richards & Son, a FORS Bronze compliant haulier) and sites must have offload facilities. Deliveries can also be made on flatbed articulated vehicles (provided by Swain, a FORS Gold compliant haulier) for offload by crane, however, only full bulk units can be ordered.

There is no additional freight charge for a full load (five bulk units). Fork extensions can be supplied if specified on an order.

Delivery zones

Customer collections

Arrangements can be made for collections from Ravago Building Solutions manufacturing facilities in King’s Lynn.

Essential questions for job sites

To ensure the smooth delivery of Ravatherm XPS X products the following questions need to be answered at the time of order:

- Do you require fork extensions?

- Are there any access restrictions?

- Can delivery site accommodate artics?

- Is a flatbed vehicle required?

- What delivery times are appropriate?

- Who are the designated delivery site contacts?

- Do you require Ravatherm XPS X UB300 for upstands? [Roofing projects only]

- Do you require Ravatherm XPS X MK for waterflow reducing layer? [Roofing projects only]

All delivery sites MUST confirm that they have their own offload facilities. It takes a minimum of one hour to offload a full load (5 bulk units).

Product Storage

Ravatherm XPS X must be protected from prolonged exposure to sunlight and should be stored under cover or protected with light-coloured opaque polythene sheets. Care must be taken to avoid contact with solvents and materials containing organic components as these can cause damage to the boards.

All boards must be stored flat, off the ground on a clean, level surface and undercover to protect them from high winds. They must not be exposed to open flame or other ignition sources and under no circumstances should damaged boards be used.

Please complete the questionnaire below. – a total of 20 points are available. After submission your responses will be checked and if you have passed (15 points) you will be emailed a certificate.